Carrier, use of a carrier, method of activating a carrier and method of making a carrier

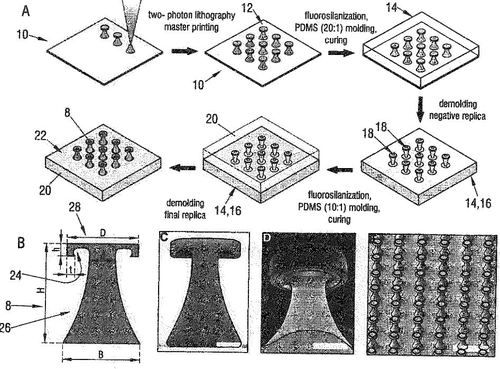

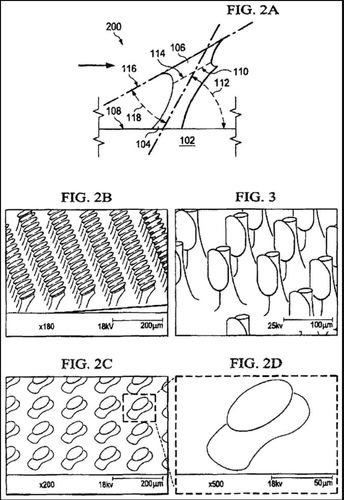

Microfibers with mushroom-shaped tips for optimal adhesion

Sitti, M., Aksak, B.

2023, US Patent 11,613,674 (patent)

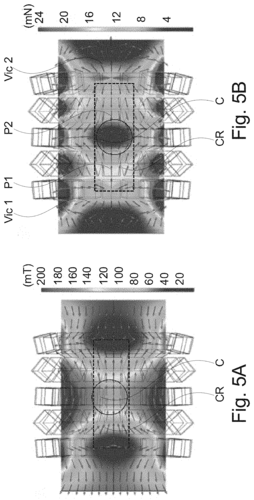

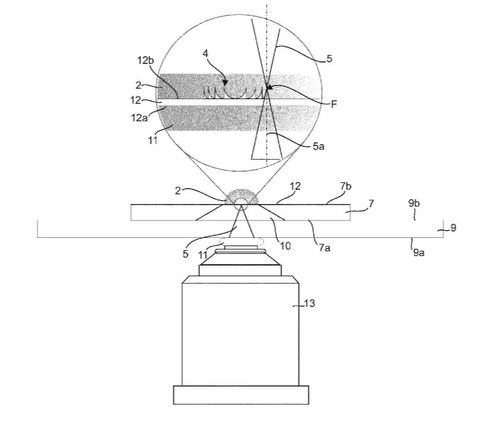

Magnetic trap system and method of navigating a microscopic device

Son, D., Ugurlu, M., Bluemer, P., Sitti, M.

2023, US Patent App. 17/871,598 (patent)

A Liquid Repellent Fibrillar Dry Adhesive Material and a Method of Producing the Same

2022

DRY ADHESIVES AND METHODS FOR MAKING DRY ADHESIVES

Metin Sitti, Michael Murphy, Burak Aksak

December 2022, US Patent App. 17/895,334, 2022 (patent)

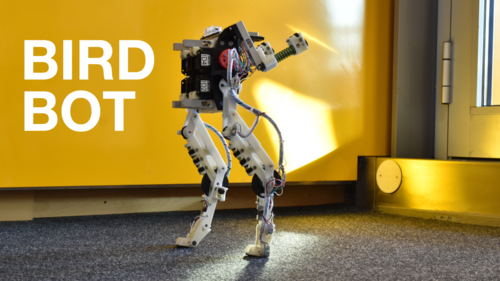

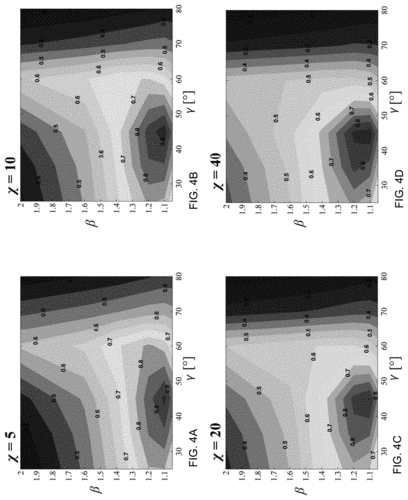

Data for BirdBot Achieves Energy-Efficient Gait with Minimal Control Using Avian-Inspired Leg Clutching

Badri-Spröwitz, A., Sarvestani, A. A., Sitti, M., Daley, M. A.

Edmond, March 2022 (techreport)

Method of making one or more fibrils, computer implemented method of simulating an adhesive force of one or more fibrils and fibril

Heat assisted magnetic programming of soft materials

Light-triggered Drug Release from 3D-printed Magnetic Chitosan Microswimmers

Scientific Report 2016 - 2021

2020

Fibrillar structures to reduce viscous drag on aerodynamic and hydrodynamic wall surfaces

Castillo, L., Aksak, B., Sitti, M.

2020, US Patent 10,830,261 (patent)

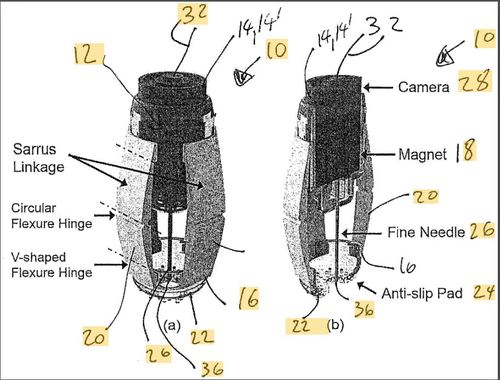

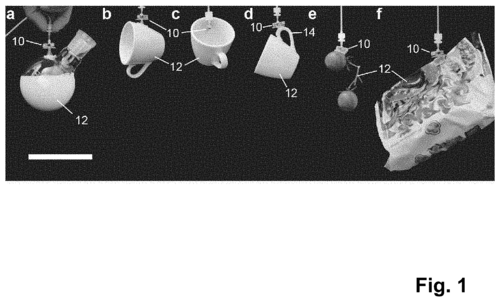

Gripping apparatus and method of producing a gripping apparatus

Song, S., Sitti, M., Drotlef, D., Majidi, C.

Google Patents, February 2020, US Patent App. 16/610,209 (patent)

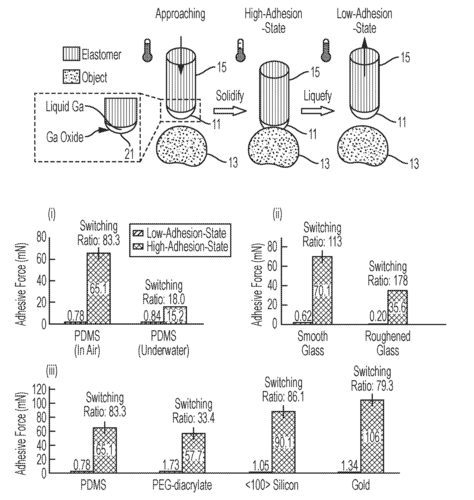

Method and device for reversibly attaching a phase changing metal to an object

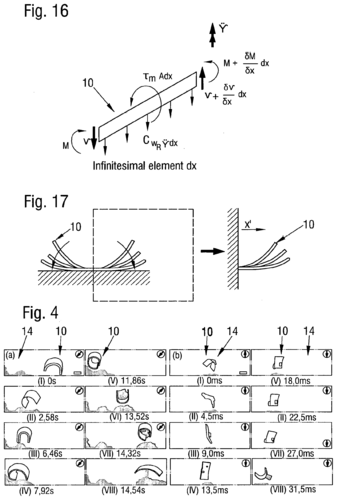

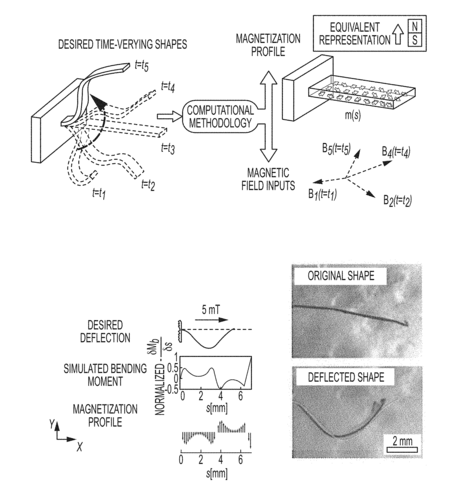

Method of actuating a shape changeable member, shape changeable member and actuating system

Hu, W., Lum, G. Z., Mastrangeli, M., Sitti, M.

Google Patents, January 2020, US Patent App. 16/477,593 (patent)

Method of fabricating a shape-changeable magentic member, method of producing a shape changeable magnetic member and shape changeable magnetic member

Method for producing an XUV and X-ray diffractive optic

SANLI, U. T., Ceylan, H., Sitti, M., SCHÜTZ, G., Keskinbora, K.

2020, US Patent App. 16/979,121 (patent)

Microfibers with mushroom-shaped tips for optimal adhesion

Sitti, M., Aksak, B.

2020, US Patent 10,689,549 (patent)

2019

Method of assembling mobile micro-machines and a mobile micro-machine

Sitti, M., Yigit, M. B., Alapan, Y., Beker, O.

2019, International Application, Sep.2019, PCT/EP2019/075564 (patent)

Scientific Report 2016 - 2018

A liquid repellent fibrillar dry adhesive material and a method of producing the same

2017

Method of molding simple or complex micro and/or nanopatterned features on both planar or non-planar molded objects and surfaces and the molded objects produced using same

Sitti, M., Glass, P. S., Aksak, B.

2017, US Patent 9,566,722 (patent)

Methods, apparatuses, and systems for micromanipulation with adhesive fibrillar structures

Sitti, M., Mengüç, Y.

US Patent 9,731,422, 2017 (patent)

2016

Remotely addressable magnetic composite micro-actuators

Sitti, M., Diller, E., Miyashita, S.

February 2016, US Patent 9,281,112 (patent)

2015

Untethered Magnetic Micromanipulation

Diller, E., Sitti, M.

In Micro-and Nanomanipulation Tools, 13, 10, Wiley-VCH Verlag GmbH & Co. KGaA, November 2015 (inbook)

Methods of forming dry adhesive structures

Sitti, M., Murphy, M., Aksak, B.

September 2015, US Patent 9,120,953 (patent)

Micro-fiber arrays with tip coating and transfer method for preparing same

Sitti, M., Washburn, N. R., Glass, P. S., Chung, H.

July 2015, US Patent 9,079,215 (patent)

Dry adhesives and methods for making dry adhesives

Sitti, M., Murphy, M., Aksak, B.

March 2015, US Patent App. 14/625,162 (patent)

2014

Addressing of Micro-robot Teams and Non-contact Micro-manipulation

Diller, E., Ye, Z., Giltinan, J., Sitti, M.

In Small-Scale Robotics. From Nano-to-Millimeter-Sized Robotic Systems and Applications, pages: 28-38, Springer Berlin Heidelberg, 2014 (incollection)

Opto-thermal micro-transportation for cellular microbiology

2012

Automated Tip-Based 2-D Mechanical Assembly of Micro/Nanoparticles

Onal, C. D., Ozcan, O., Sitti, M.

In Feedback Control of MEMS to Atoms, pages: 69-108, Springer US, 2012 (incollection)

2011

Automated Control of AFM Based Nanomanipulation

Xie, H., Onal, C., Régnier, S., Sitti, M.

In Atomic Force Microscopy Based Nanorobotics, pages: 237-311, Springer Berlin Heidelberg, 2011 (incollection)

Teleoperation Based AFM Manipulation Control

Xie, H., Onal, C., Régnier, S., Sitti, M.

In Atomic Force Microscopy Based Nanorobotics, pages: 145-235, Springer Berlin Heidelberg, 2011 (incollection)

Descriptions and challenges of AFM based nanorobotic systems

Xie, H., Onal, C., Régnier, S., Sitti, M.

In Atomic Force Microscopy Based Nanorobotics, pages: 13-29, Springer Berlin Heidelberg, 2011 (incollection)

Applications of AFM Based Nanorobotic Systems

Xie, H., Onal, C., Régnier, S., Sitti, M.

In Atomic Force Microscopy Based Nanorobotics, pages: 313-342, Springer Berlin Heidelberg, 2011 (incollection)

Nanomechanics of AFM based nanomanipulation

Xie, H., Onal, C., Régnier, S., Sitti, M.

In Atomic Force Microscopy Based Nanorobotics, pages: 87-143, Springer Berlin Heidelberg, 2011 (incollection)

Instrumentation Issues of an AFM Based Nanorobotic System

Xie, H., Onal, C., Régnier, S., Sitti, M.

In Atomic Force Microscopy Based Nanorobotics, pages: 31-86, Springer Berlin Heidelberg, 2011 (incollection)

2010

Nanohandling robot cells

Fatikow, Sergej, Wich, Thomas, Dahmen, Christian, Jasper, Daniel, Stolle, Christian, Eichhorn, Volkmar, Hagemann, Saskia, Weigel-Jech, Michael

In Handbook of Nanophysics: Nanomedicine and Nanorobotics, pages: 1-31, CRC Press, 2010 (incollection)

Atomic-Force-Microscopy-Based Nanomanipulation Systems

Onal, C. D., Ozcan, O., Sitti, M.

In Handbook of Nanophysics: Nanomedicine and Nanorobotics, pages: 1-15, CRC Press, 2010 (incollection)

2009

Biologically Inspired Polymer Microfibrillar Arrays for Mask Sealing

Cheung, E., Aksak, B., Sitti, M.

CARNEGIE-MELLON UNIV PITTSBURGH PA, 2009 (techreport)

2008

Biologically Inspired Polymer Micro-Patterned Adhesives

Cheung, E., Sitti, M.

EDGEWOOD CHEMICAL BIOLOGICAL CENTER ABERDEEN PROVING GROUND MD, 2008 (techreport)

2007

Bacteria integrated swimming microrobots

Behkam, B., Sitti, M.

In 50 years of artificial intelligence, pages: 154-163, Springer Berlin Heidelberg, 2007 (incollection)