Wireless small-scale magnetic medical robots must be made of biocompatible (and even biodegradable) materials for their safe use inside the human body. While we have many options for biocompatible/degradable non-magnetic robot materials, we are limited by the magnetic micro/nanoparticle and nanofilm coating materials that we could integrate to the robot body. We require strong magnetic properties for these materials to actuate them easily with reasonable external magnetic fields/gradients, while typical strong magnetic actuation materials, such as NdFeB microparticles, are toxic. Therefore, we have explore several magnetic material systems to enable biocompatible small-scale robots with relatively strong magnetic properties.

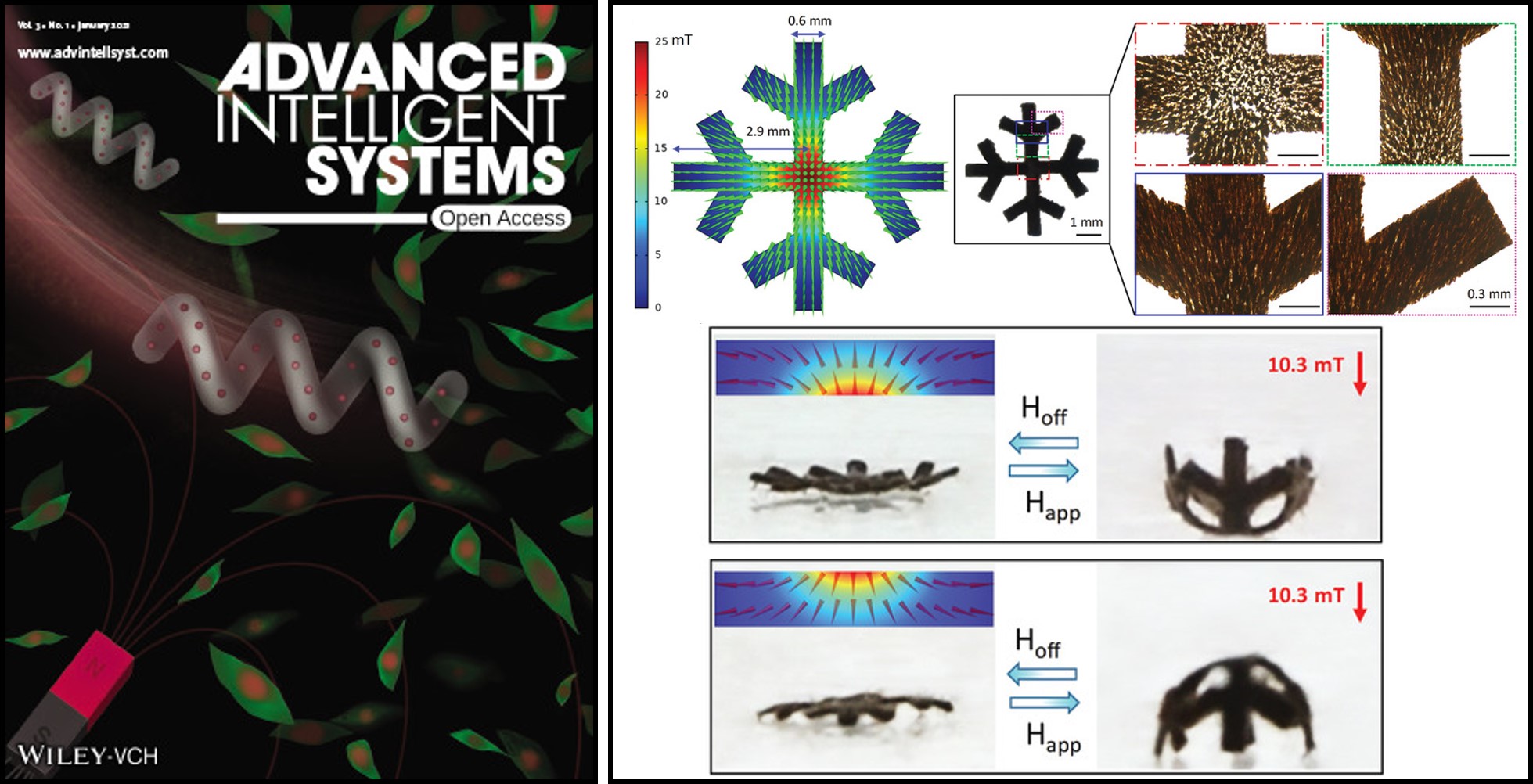

First, we have explored the aligned self-assembled chains of iron oxide nanoparticles embedded inside 3D-printed hydrogel robot bodies to create magnetically actuated robots [ ], such as a wireless soft milligripper. Such shape-programmable gripper can perform cargo grabbing, transportation by rolling, and release by controlling magnetic field inputs. It is shown to be biocompatible and even biodegradable (completely degraded by the matrix metalloproteinase-2 enzyme in physiologically relevant concentrations) inside the body. This approach offers a facile fabrication strategy for designing biocompatible and biodegradable magnetic soft robots using nanocomposite materials with programmable 3D magnetic anisotropy toward future medical applications.

Next, we have used ferromagnetic and biocompatible iron platinum (FePt) nanoparticle-based 3D microprinting of small-scale robots using two-photon polymerization [ ]. We have shown 30 μm-long helical magnetic microswimmers using such material composition with significantly enhanced swimming performance with compared to iron oxide nanoparticle-base printed microswimmers. As an alternative approach, we can also sputter coat FePt nanofilms on 3D-printed inorganic robot bodies for creating biocompatible magnetic robots with strong magnetic actuation properties [ ]. Here, the FePt film needs to be annealed at high temperatures, which limits the type of inorganic robot materials.