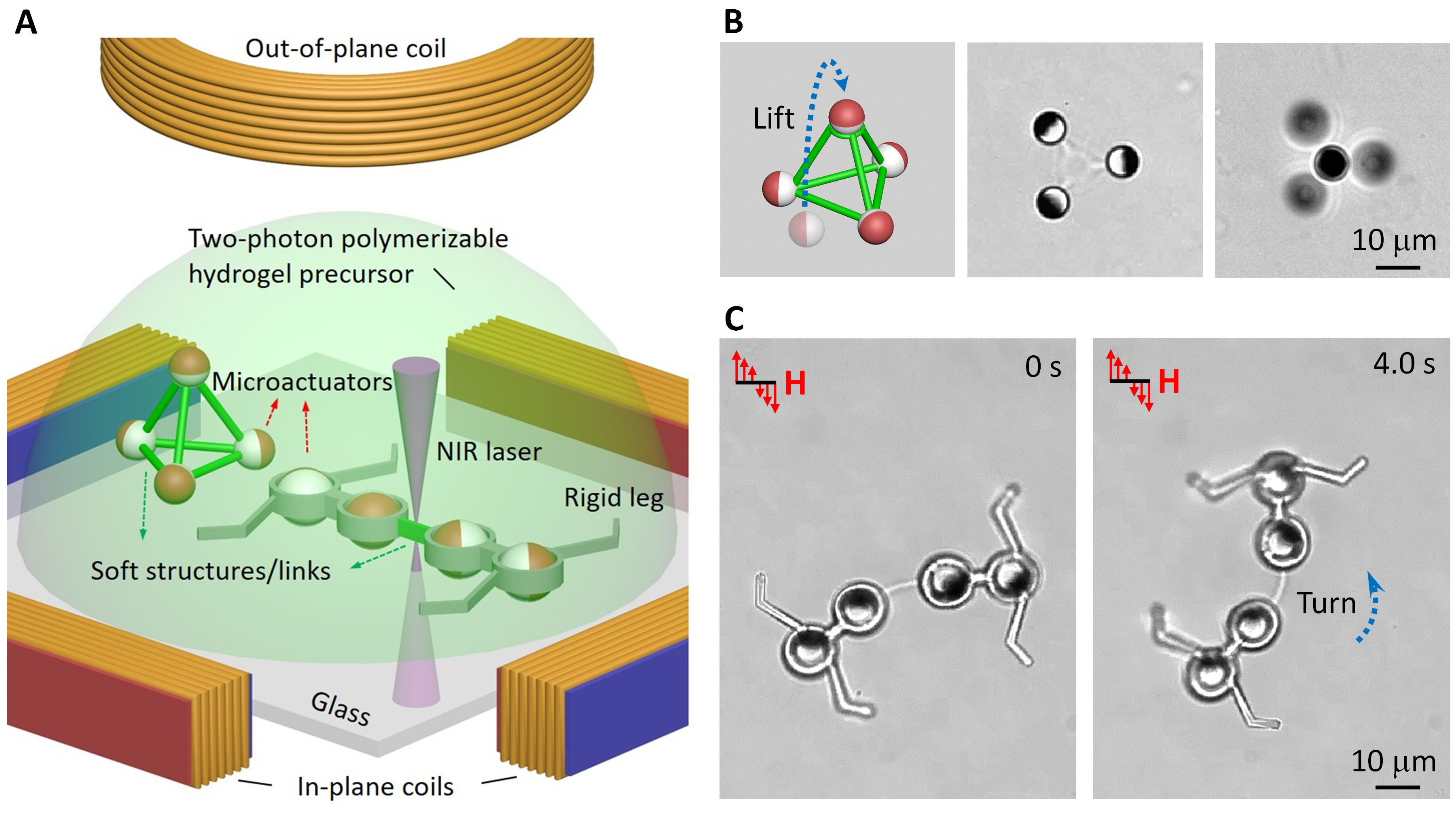

A) Soft micromachine fabrication strategy: fabrication process schematics of soft micromachines using a two-photon polymerization-based 3D microprinting system with an integrated electromagnetic coil setup. The microactuators (spherical Janus microparticles) are manipulated to reach a desired position and orientation and fixed there temporarily using 3D microprinting. Soft and rigid materials can be 3D-printed on a fixed microactuator to link it with various other fixed microactuators. B) Example 2D and 3D soft microactuator structures. C) Example legged soft microrobot with a soft body structure and rigid legs to walk on surfaces.

Soft mobile microrobots with overall sizes less than 100 micrometer would enable diverse programmed shape transformations and functions for future biomedical and organ-on-a-chip applications. However, fabrication of such machines has been hampered by the lack of control of microactuator’s programmability. To address such challenge, we use two-photon polymerization to selectively link Janus microparticle-based magnetic microactuators by 3D printing of soft or rigid polymer microstructures or links [ ]. Sequentially, we position each microactuator at a desired location by surface rolling and rotation to a desired position and orientation by applying magnetic field–based torques, and then 3D printing soft or rigid links to connect with other temporarily fixed microactuators. The linked 2D microactuator networks exhibit programmed 2D and 3D shape transformations, and untethered limbless and limbed micromachine prototypes exhibit various robotic gaits for surface locomotion. Furthermore, the microactuators can also be positioned in 3D space as a preliminary step towards 3D future configurations, either by levitating the microactuators in the vertical axis using 3D gradient fields or by a rolling motion along the 3D-microprinted hydrogel beam. The proposed fabrication strategy can enable new soft micromachine designs and applications at the cellular scales. By implementing this method layer-by-layer, 3D soft actuator networks can be also created in the future towards more complex soft microrobots.